Gardner Color Standards: The Key to Reliable Liquid Color Evaluation

In industries where color plays a critical role—such as paints, coatings, chemicals, and food products—accurate color evaluation is essential. For liquid materials, achieving consistent color can be particularly challenging due to variations in raw materials, batch processes, and environmental factors. This is where Gardner color standards come into play, providing a reliable reference for liquid color measurement. Combined with modern paint color measurement techniques and color analysis software, these standards help manufacturers maintain quality, consistency, and customer satisfaction.

What Are Gardner Color Standards?

Gardner color standards are a set of reference liquids developed to quantify the color of yellow-to-brown shades in transparent or semi-transparent liquids. Originally created for varnishes and resins, these standards have become widely adopted in industries where liquid color is critical.

Each Gardner standard corresponds to a specific degree of color intensity, allowing technicians to visually or instrumentally compare a sample against a known reference. This system simplifies the evaluation of liquid color, ensuring that measurements are consistent, reproducible, and comparable across laboratories and production lines.

The Importance of Gardner Standards in Liquid Color Evaluation

Accurate liquid color measurement is vital for several reasons:

- Quality Control: Variations in color can indicate differences in raw materials, improper mixing, or potential degradation of products.

- Brand Consistency: Customers expect uniformity in color, especially in paints, coatings, and chemical products.

- Regulatory Compliance: Certain industries require adherence to color specifications for safety, labeling, and certification.

- Efficiency: Early detection of color deviations reduces waste and prevents costly rework.

Gardner color standards provide a reliable benchmark, making it easier to maintain these quality objectives.

Integrating Gardner Standards with Paint Color Measurement – Meet ASTM D1544 & Win Customer Trust

While Gardner standards originated for visual comparison, modern paint color measurement instruments allow for objective, numerical evaluation. Instruments such as spectrophotometers and colorimeters can quantify liquid color and compare results against Gardner references, reducing human error and improving precision.

Key benefits of integrating Gardner standards with paint color measurement include:

- Consistency: Numerical measurements complement visual inspection, ensuring batch-to-batch uniformity.

- Accuracy: Instruments detect subtle differences that may be imperceptible to the naked eye.

- Documentation: Quantitative data enables detailed reporting and compliance verification.

This combination of traditional standards and modern instrumentation ensures reliable color evaluation in liquid products.

Role of Color Analysis Software – Cut Testing Time by 50%

To fully leverage Gardner color standards, manufacturers often use color analysis software. This software helps interpret measurement data, compare samples against standards, and maintain detailed records. Features of color analysis software include:

- Automated Comparison: Quickly compare sample color with multiple Gardner standards to determine exact matches.

- Trend Monitoring: Track changes in color over time to detect inconsistencies in production or storage conditions.

- Batch Analysis: Evaluate multiple samples efficiently, ensuring quality across entire production runs.

- Reporting and Documentation: Generate standardized reports for internal quality control and regulatory compliance.

By integrating color analysis software with paint color measurement tools, manufacturers can streamline their color evaluation process and make data-driven decisions.

From Lab to Factory Floor: How Gardner Color Standard Applications Boost Quality

As a globally recognized liquid color evaluation system, Gardner Color Standards offers precise grading from 1 (pale yellow) to 18 (dark brown), turning “subjective color perception” into “objective data”. Whether for coating production quality control, petroleum product color assessment, or plastic additive color compliance, it ensures every batch of your product aligns with standards—eliminating order losses caused by color deviations!

4 Key Applications for Paints, Oils & Resins, Gardner standards are widely used across industries that rely on precise liquid color evaluation:

1. Paints and Coatings

In the paint industry, consistency in color is paramount. Gardner standards allow manufacturers to monitor yellow-to-brown shades, ensuring that products match the desired appearance. Combining Gardner references with paint color measurement instruments helps maintain uniformity across multiple production batches.

2. Varnishes and Resins

Varnishes and resins often require strict color control for both functional and aesthetic purposes. Gardner standards provide a clear, objective benchmark, helping manufacturers maintain high-quality products that meet customer expectations.

3. Chemicals and Dyes

Industrial chemicals, including solvents, adhesives, and dyes, must meet precise color specifications. Gardner standards offer a reliable reference for evaluating transparency, hue, and intensity, improving product consistency and quality control.

4. Food and Beverages

Although less common in food, Gardner-like standards are sometimes used to assess the color of liquid ingredients such as syrups, oils, and beverages. Accurate color evaluation ensures product quality, visual appeal, and compliance with industry regulations.

Benefits of Using Gardner Standards with Modern Technology

Gardner Color Standards, certified by authoritative institutions, covers lubricants, fatty acids, polymers, and more. It’s the universal “color communication language” across supply chains. Showing customers that “every batch passes Gardner Color Standard testing” not only cuts communication costs but also conveys a “professional, reliable” brand image—keeping old customers coming back and attracting new ones proactively!

Combining Gardner color standards with modern measurement tools and software provides several advantages:

- Objective Evaluation: Reduces reliance on subjective visual assessments.

- Enhanced Accuracy: Detects subtle differences that may impact product quality or consumer perception.

- Efficiency: Speeds up quality control by providing fast, reproducible measurements.

- Data-Driven Quality Control: Enables manufacturers to track, analyze, and optimize color across multiple batches.

- Consistency Across Locations: Ensures that color standards are maintained across different production sites or laboratories.

These benefits help manufacturers maintain high-quality products, reduce waste, and strengthen brand reliability.

Best Practices for Reliable Liquid Color Evaluation

Most importantly, it meets international standards like ASTM D1544 and ISO 4630, helping you pass customer factory audits and export compliance checks effortlessly, no more repeated revisions for “non-compliant colors”! To maximize the effectiveness of Gardner standards and paint color measurement, consider the following practices:

- Calibration: Regularly calibrate instruments to maintain accuracy and reliability.

- Controlled Lighting: Perform measurements under standardized lighting to avoid visual discrepancies.

- Sample Preparation: Ensure liquids are homogeneous and free from bubbles or contaminants before measurement.

- Integration with Software: Use color analysis software to interpret data, track trends, and maintain comprehensive records.

- Staff Training: Educate personnel on proper measurement techniques, standards usage, and data interpretation.

Following these practices ensures that liquid color evaluation is both accurate and repeatable.

Conclusion

Gardner color standards remain a cornerstone of reliable liquid color evaluation, providing a trusted benchmark for industries ranging from paints and coatings to chemicals and food products. When combined with modern color measurement instruments and advanced color analysis software, manufacturers can achieve precise, objective, and repeatable results.

By integrating these tools and standards into production workflows, companies can maintain consistent quality, reduce waste, and meet both regulatory and customer expectations. Whether for industrial paints, resins, or other liquid products, Gardner color standards continue to play a vital role in ensuring reliable color evaluation and high-quality production outcomes.

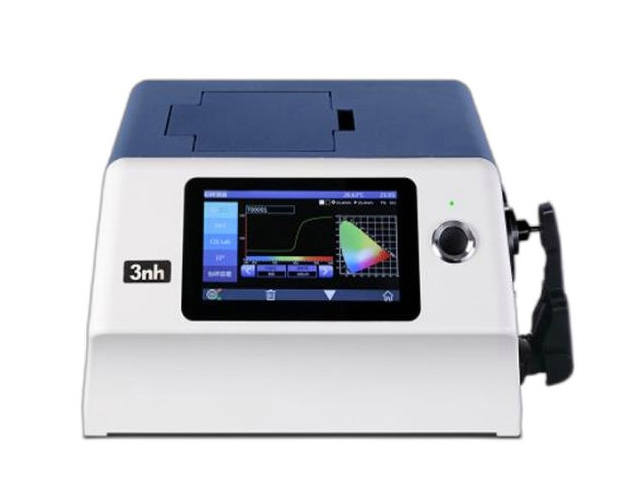

The Liquid YS6060 Spectrophotometer color meters is designed by 3NH specifically for customers who need to measure the color of transparent products. It can measure the color of liquids at room temperature or high temperatures, such as methanol, sodium methoxide, ethylene glycol, bisphenol A, electrolyte, various oils’ Lab color, Pt-Co platinum-cobalt color APHA, Hazen blackening index, Gardner Gardner color, Saybolt Saybolt color, ASTM D1500, acid washing color, ADMI, LovR, LovY LovR color, etc. It is commonly used in quality control and color management fields to ensure color consistency in product production.

3nh is a high-tech enterprise in the field of color detection, mainly engaged in the research and development, production, and sales of color detection equipment. Its products include precision colorimeters, spectrophotometers, glossiness meters, haze meters, paint and ink color matching software, image testing chart cards, and optical image testing solutions. Widely used in industries and research institutions such as printing, coatings, auto parts, metals, home appliances, cameras, etc. both domestically and internationally, with multiple innovative patents and industry-leading technology!