How to Design Right Bakery Boxes

How to design right When you design a bakery box, you need to consider safety, oil resistance, moisture resistance, cost-effectiveness, and FDA/EU food contact safety, so that your baked snacks can be safe, fresh, and sell well. Benfang will help you choose and design the right bakery box.

Last updated: September 2025 | Reading time: 7 minutes

This article will answer your questions

- What size boxes are suitable for different baked goods?

- What materials are best for making bakery boxes?

- How to design bakery boxes to keep food fresh?

- What printing methods can make bakery boxes stand out?

- How do eco-friendly baking boxes enhance your brand image?

- Which box designs make shipping easier?

- How do customized bakery boxes improve customer experience?

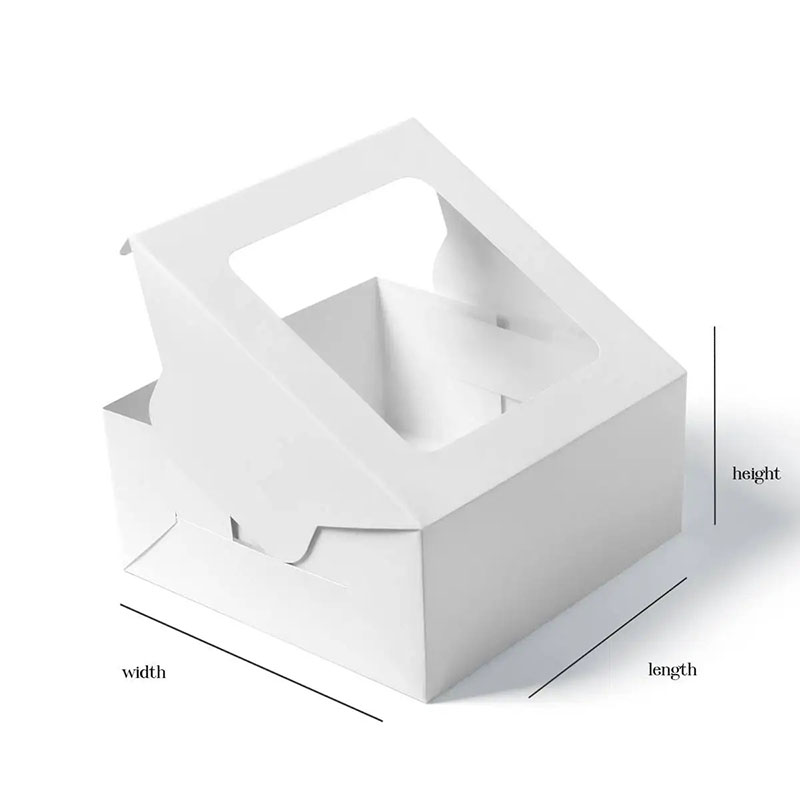

What size boxes are suitable for different baked goods?

Baked goods come in all shapes and sizes, so each requires a corresponding box. Oversized boxes can increase shipping costs, while undersized boxes can easily crush cookies. 6x6x3 inches is ideal for cookies, 8x8x4 inches for small cakes, and 14x10x5 inches for whole cakes. Obviously, an inappropriately sized box can easily cause the food to move around inside, increasing the risk of damage.

Experienced bakeries will choose baking boxes with automatic locking bottoms or flat-pack shipping because they are lightweight goods, thus reducing UPS’s volume and weight charges. The optimized box structure can save 20-30% of transportation costs.

Common baking box sizes

| Product Types | Size (inches) | Box Style | Your Benefits |

| Cookies | 6 x 6 x 3 | Auto-lock | Saves storage space |

| Donuts | 10 x 8 x 3 | Window box | Enhances display appeal |

| Bread | 12 x 6 x 4 | Folding box | Better fit, prevents deform |

| Whole Cake | 14 x 10 x 5 | Corrugated F-flute | Stacking strength in transport |

- Cookies: Use a small square box with an inner tray to prevent movement.

- Donuts: Choose a box with a window and ventilation holes to prevent the frosting from getting wet.

- Cake: Test stacking of more than 10 layers to ensure stable transportation.

Case: A Chinese bakery chain changed its square croissant boxes to rectangular self-locking boxes, saving 28% of storage space and reducing UPS shipping costs by 22%.

What materials are best for bakery boxes?

Food safety always comes first. Use only FDA/EU certified food-grade cardboard and glue. Cheap recycled paper can release harmful substances and contaminate your bread or cakes.

White cardboard + PE coating → oil and sugar resistant, best for regular cakes

Kraft paper + PLA coating → environmentally friendly and biodegradable, suitable for green brands

Corrugated E-flute cardboard → High strength, suitable for wholesale transportation

Material comparison table

| Materials | Moisture & Oil Resistance | Eco-Friendliness | Best Use |

| Whiteboard + PE | High | Medium | Everyday cakes |

| Kraft + PLA | Medium–High | High | Eco-conscious buyers |

| Corrugated E-flute | High | Medium | Large cake shipping |

- Ask for a certificate of compliance from the carton factory.

- Aqueous barrier coating for fatty snacks.

- Note when exporting: Many EU retailers prohibit PVC windows.

Read more: customize kraft paper boxes

How to design bakery boxes to keep food fresh?

Moisture and oil resistance are key. Ordinary kraft paper boxes soften within a few hours. Adding an inner coating (PE, PLA, or a water-based coating) can extend the shelf life of food by 2–3 days.

Breathability is also important. Tiny holes in the folds keep the bread crispy. Boxes with windows look good, but they can trap steam, which can easily flow onto the bread and spoil it.

Key points of fresh-keeping design

- Inner barrier coating → prevents oil leakage

- PLA window film → biodegradable and transparent

- Air holes → keep the bread’s texture

Actual test: A bakery in Hangzhou tested five types of air vent diameters and found that 2mm was the best, which could both maintain the taste and prevent dust.

What printing methods can make bakery boxes stand out?

Packaging is a secondary advertisement for baked goods. Oil, glare, and moisture will cause poor-quality printing to fade. We recommend using soy-based ink or water-based flexo ink.

Matt film + local UV → enhance brand sense

Hot stamping → Suitable for high-end cake brands

Water-based ink → Complies with environmental regulations

How do eco-friendly baking boxes enhance your brand?

Environmentally friendly packaging has evolved from a trend to a requirement, with the EU and US markets requiring FSC-certified kraft paper and biodegradable windows.

- Many consumers now ask: Can it be degraded?

- Retailers banned from using PVC windows

- Environmentally friendly packaging can increase repeat purchases and brand trust

Green bakery boxes are an opportunity to improve your image and help you enter more distribution channels.

Which box designs make shipping easier?

Strength and stacking performance are particularly critical for wholesale bakery boxes. Boxes that fail the ECT test are prone to collapse.

- For large cakes, it is recommended to use E-flute or F-flute trays.

- Reinforced carrying handles for cream cakes

- Use flat boxes to reduce storage costs

Case: A supplier in Shenzhen shipped cake boxes without ECT testing, resulting in 40% of 500 boxes collapsing. After switching to corrugated inner trays, the breakage rate dropped to 2%.

How do customized bakery boxes improve customer experience?

Custom bakery boxes enhance your customer experience and strengthen your brand. Customers appreciate boxes with handles, double-walled sides, and a clean, easy-to-open design. A positive unboxing experience can lead to repeat purchases.

Customizable elements:

Internal printing of brand story or logo

Ribbon gift box suitable for festivals or gifts

Window + inner support combination enhances the sense of luxury

New trends in bakery boxes in 2025

- Degradable coating: Water-based coating and PLA replacing PE film

- Logistics-friendly design: More self-locking bottom and flat-pack boxes

- Hybrid printing: Flexo + digital combination, supporting small batch personalization

Industry data shows that by 2025, the demand for environmentally friendly baking packaging in Europe and the United States will increase by 18%.

FAQs

Q1: What is the use of a baking box with a window?

You can directly display baked delicacies to your customers and increase their impulse to buy, but ventilation holes must be used to prevent food from getting damp.

Q2: Are ribbon baking boxes only suitable for high-end cakes?

No. Ribbons enhance the gift value and are also commonly used on cookies and bread.

Q3: How to ensure food safety in baking boxes?

Use FDA/EU approved coatings and glues, and do not use uncertified recycled cardboard.

Conclusion

Choosing the right bakery box isn’t just about appearance. Food safety, freshness preservation, crush resistance, and user experience are equally important. Customized, eco-friendly bakery boxes can protect food and enhance your brand.

About XiangGe Package

Xiangge specializes in providing customized bakery boxes to customers worldwide. We use FSC-certified kraft paper, food-grade coatings, and high-end printing techniques. With over 10 years of export experience, we help bakery brands design packaging that is safe, cost-effective, and enhances their brand image.

Contact us for a free proof or custom die design.

Last updated: September 2025