The Advantages of Loop Cutting: ESH300-2T Horizontal Diamond Wire Saw Explained

In today’s rapidly evolving manufacturing and material-processing industries, precision and efficiency are everything. Whether you’re slicing brittle crystals, advanced ceramics, or composite materials, the quality of your cut can significantly impact the final product. One technology leading this charge is loop cutting, particularly with the use of a Diamond Wire Loop. Among the top machines leveraging this cutting-edge approach is the ESH300-2T Horizontal diamond looped wire saw machine—a powerhouse in both laboratory and industrial settings.

So what makes loop cutting so advantageous, and why is the ESH300-2T quickly becoming a preferred tool for precision cutting professionals? Let’s break it down.

What Is Loop Cutting?

Loop cutting involves a continuous diamond wire loop moving in one direction across a material surface. Unlike reciprocating or rotating blade systems, the wire doesn’t reverse or create back-and-forth friction. Instead, the loop glides with consistency, allowing for ultra-fine, stress-free cuts across a range of brittle and delicate materials.

The Diamond Wire Loop is embedded with micro-diamonds, which do the cutting as the wire moves across the material. This approach minimizes damage, heat, and material loss, making it ideal for sensitive materials like semiconductors, quartz, and ceramics.

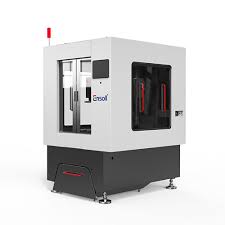

Introducing the ESH300-2T Horizontal Diamond Looped Wire Saw Machine

Engineered for precision and efficiency, the ESH300-2T Horizontal diamond looped wire saw machine is a versatile tool designed to deliver consistent results in demanding environments. Whether you’re in a research lab or a production facility, this machine provides a reliable solution for achieving perfect cuts every time.

Key Features:

- Horizontal configuration ideal for slab slicing and flat material cutting.

- Advanced wire loop system for uniform tension and speed control.

- Touchscreen interface for user-friendly operation and parameter adjustments.

- Large worktable to accommodate various material sizes and shapes.

- Minimal kerf loss for better material yield.

The Benefits of Diamond Wire Loop Cutting

1. Unmatched Precision

The diamond wire loop enables cutting down to the micrometer scale. This is especially valuable when dealing with delicate substrates like sapphire wafers, silicon crystals, or optical glass. The ESH300-2T is engineered to maximize that precision with high wire stability and accurate control systems.

2. Reduced Material Loss

Thanks to its thin wire diameter and smooth, continuous movement, loop cutting produces less kerf (material lost as dust during cutting). This is a game-changer for expensive or rare materials where every millimeter matters.

3. Low Thermal Impact

Traditional saw blades can generate heat during cutting, which leads to thermal deformation or internal stress. In contrast, Diamond Wire Loop cutting is low-heat, minimizing thermal distortion and making it ideal for heat-sensitive materials like crystals and composites.

4. Versatility Across Materials

The ESH300-2T can cut a wide variety of materials, including:

- Quartz and other crystals

- Ceramics

- Silicon

- Glass

- Ferrites

- Composites

This wide range of compatibility makes it a great all-around machine for facilities working with diverse materials.

Why Choose the ESH300-2T?

Beyond just the cutting method, the ESH300-2T Horizontal diamond looped wire saw machine brings added advantages that set it apart from the competition.

Efficiency

With automated tensioning, programmable speeds, and precision wire guidance, the machine minimizes downtime and boosts output. This means more cuts per hour with less rework.

Durability

The robust build of the ESH300-2T ensures it can run for extended periods with minimal maintenance. The Diamond Wire Loop itself also lasts longer due to the consistent and gentle cutting action.

Operator-Friendly

Despite its advanced features, the ESH300-2T is designed with simplicity in mind. The touchscreen control panel allows for quick adjustments, real-time monitoring, and easy calibration—even for operators who are not engineers.

Ideal Applications

The ESH300-2T is used across various high-tech industries, including:

- Semiconductor manufacturing

- Photovoltaic (solar panel) production

- Research and development labs

- Optics and photonics

- Advanced ceramics fabrication

If your operation involves Diamond Wire Loop technology or crystal processing, this machine is built to elevate your precision and productivity.

Final Thoughts

The combination of loop cutting technology and the precision engineering of the ESH300-2T Horizontal diamond looped wire saw machine offers an unbeatable solution for modern material slicing needs. With its ability to handle delicate and expensive materials with ease, it not only improves cut quality but also saves time, reduces waste, and enhances operational efficiency.

In an industry where even the smallest imperfections can lead to big problems, investing in the right cutting machine is essential. The ESH300-2T delivers the control, quality, and confidence professionals need to get the job done right—every single time.